Polyester Mesh Belt for Sludge Dewatering and Filter Presses

This high-performance industrial filter material is widely used in wastewater treatment, chemical processing, textile dyeing, steelmaking, papermaking, and other industries. It is engineered for superior strength, acid and alkali resistance, wear resistance, permeability to air and water (while remaining impermeable to sludge), and effective solid-liquid separation. Its design facilitates easy sludge release after pressing, simplifying cleaning and maintenance.

Material

- Main Component: Polyester fiber, typically polyethylene terephthalate (PET)

- Auxiliary Materials: Additives (anti-aging, anti-oxidation) and coatings (polyurethane) to enhance wear and corrosion resistance.

Classifications

By Weave:

- Single-layer

- Double-layer

- Two-and-a-half-layer

- Three-layer

- Herringbone

By Application:

- Sludge dewatering mesh

- Belt filter press belt

- Rubber belt vacuum filter belt

- Horizontal vacuum belt filter belt

By Material:

- Standard polyester

- High-strength polyester

- High-temperature resistant polyester

Specifications

- Yarn Diameter: 0.5 mm to 0.9 mm (customizable)

- Density: 16 to 30 threads/cm (customizable)

- Air Permeability: 500 m³/m²/h to 9000 m³/m²/h (customizable)

- Radial Breaking Strength: Up to 2100 N/cm (customizable)

- Mesh Count: 6 mesh to 120 mesh (customizable)

- Width: 1 meter to 5 meters (customizable)

- Thickness: 0.5 mm to 1.5 mm (depending on layers and weave)

- Length: Customizable to fit equipment needs

- Monofilament Diameter: 0.3 mm to 1.2 mm

- Aperture Size: 0.1 mm to 5 mm

- Weight: 300 g/m² to 1200 g/m²

- Temperature Resistance: -40°C to +180°C

- pH Tolerance: 2 to 12

- Joint Types: Metal buckle, spiral, ring, endless

- Edge Reinforcement: Resin, canvas, heat sealing

Features

- High Strength: Polyester fibers provide exceptional tensile strength for stable operation under heavy loads.

- Chemical Resistance: Withstands acids, alkalis, and other common chemicals, prolonging service life.

- Abrasion Resistance: Suitable for harsh industrial environments, reducing replacement frequency.

- Permeability: Optimized for efficient dewatering and rapid solid-liquid separation.

- Non-Clogging: Effectively captures sludge and prevents solid particles from penetrating.

- Easy Cleaning: Sludge releases easily for simplified maintenance.

- Wide Applications: Suitable for diverse sludge dewatering and filtration applications.

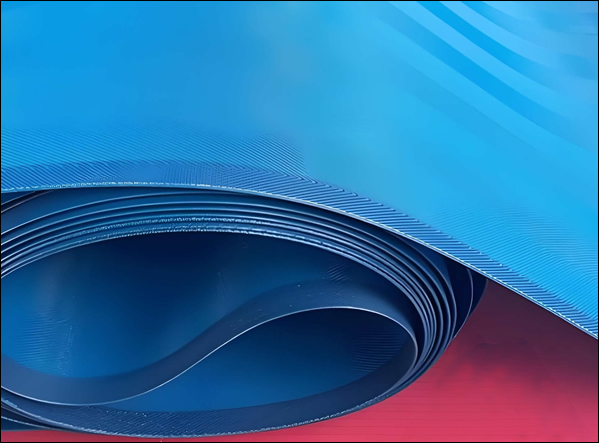

Polyester Mesh Belt for Sludge Dewatering

Polyester Belt for Sludge Dewatering in Filter Presses

Sludge Dewatering Polyester Belt Featuring Ring Joint Connection

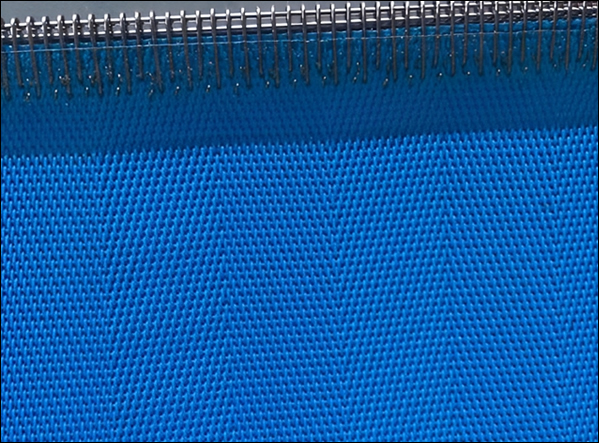

Polyester Mesh Dewatering Belt with Metal Buckle Joint

Polyester Mesh Dewatering Belt with Metal Buckle Fastening

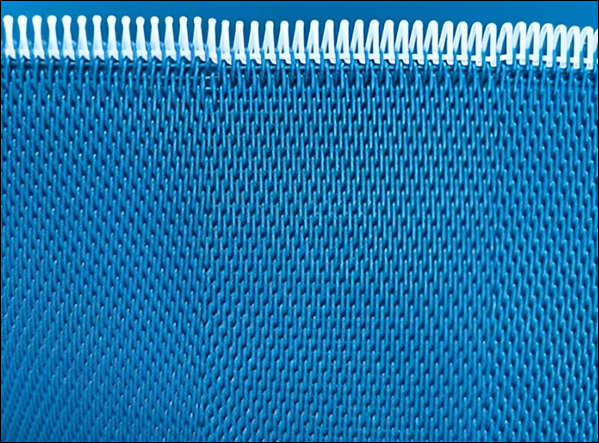

Spiral Polyester Mesh Screen Conveyor Belt

| Model | Wire diameter mm |

Density Root/10cm |

Air permeability m3/m2h |

Net weight g/㎡ |

Strength kg/cm |

Used in | ||

| Warp | Weft | Warp | Weft | |||||

| WNW14803 | 0.7 | 0.8 | 142 | 47-60 | 3900- 8500 |

1400 | 240 | Sludge, Squeeze juice |

| WNW16803 | 0.7 | 0.8 | 156 | 46-50 | 6000 | 1400 | 265 | Sludge, Squeeze juice |

| WNW16904 | 0.75 | 0.9 | 156 | 47 | 8000 | 1800 | 280 | Iron and steel industry sludge dewatering Living sludge dewatering |

| WNW121054 | 0.9 | 1.05 | 120 | 42 | 8000 | 1650 | 340 | Iron and steel industry sludge dewatering |

| WNW22903 | 0.5 | 0.9 | 220 | 50-55 | 9000- 10000 |

1200 | 200 | Living sludge dewatering |

| WNW20703 | 0.5 | 0.7 | 200 | 70 | 10000 | 1000 | 185 | Living sludge dewatering Chemical sludge dewatering |

| GW24504 | 0.5 | 0.5 | 240 | 130-140 | 8500- 10000 |

1180 | 220 | Paper dry network Paper sludge dewatering |

| WNW08903 | 0.9 | 0.9 | 78 | 50 | 8500 | 1430 | 210 | Industrial sludge dewatering |

| WNW16704 | 0.7 | 0.7 | 160 | 90 | 12000 | 1350 | 265 | Building materials industries |

| WNW26908 | 0.5 | 0.9 | 26.4 | 69-75 | 5000- 5500 |

1364 | 240 | Viscosity of the larger Sludge |

| CXW12 Mesh | 0.75 | 0.8 | 47 | 48 | 650 | 94 | Paper pulp washing | |