New Product Launch and Export Specifications for Polyester Mesh Screen Fabric

Pertter Polyester Mesh Fabric Co. introduces its latest line of polyester mesh screen fabrics, featuring new product launches and comprehensive export specifications. This column provides up-to-date information on our advanced mesh products, designed to meet diverse industrial needs. We offer customized specifications, ensuring clients receive tailored solutions that align with their specific applications and international standards. Our new product range emphasizes enhanced durability, precision, and performance, reflecting our commitment to innovation and quality in polyester mesh manufacturing.

Polyester Mesh Fabric for Electrodialysis Membrane Support

Pertter Polyester Mesh Fabric Co. offers specialized polyester mesh designed as a support layer for ion-exchange electrodialysis membranes. Our mesh provides structural reinforcement and optimized flow characteristics, enhancing membrane performance and durability.

Polyester Mesh Specifications

- Material: 100% Polyester

- Width: 860 mm

- Sample: 1 m² for testing

- Weave: 32 Ends/cm (Warp), 35 Picks/cm (Weft)

- Loop Size: 258 µm (Warp), 231 µm (Weft)

- Open Area: 67%

- Fiber Diameter: 55 µm (Warp & Weft)

- Finishing: Thermal Fixed

- Stability (160°C): Warp <1.0% change, Weft <0.8% change

- Strength: Warp >390 N/cm, Weft >420 N/cm

- Flow: 67% Open Area

- Tolerances: Width ±1%, Length ±2%, Aperture/Mesh ±3%

100% Polyester Knitted Screen

100% Polyester Knitted Screens offer a versatile and durable solution for a range of industrial and commercial applications. These screens are produced using a specialized knitting process, which yields a fabric with unique properties compared to woven screens. The knitted structure provides enhanced flexibility and conformability, allowing for use in applications with complex shapes or where movement is required. Polyester's inherent properties, such as chemical resistance, temperature stability, and high tensile strength, are retained in the knitted form. The knitted construction can be engineered to achieve specific pore sizes and air permeability, enabling precise control over filtration and drying processes. Their ease of cleaning and maintenance further contributes to their practicality and longevity.

- Color: Natural White

- Material Composition: 100% Polyester

- Fabric Weight: ≤ 12 g/m²

- Mesh Density: 15–20 mesh/cm²

- Burst Strength: Approx. 1.0 kgf/cm²

- Thickness: ≤ 0.15 mm

- Working Temperature (Intermittent): -25°C to +150°C

- Working Temperature (Continuous): -25°C to +120°C

- Thermal Conductivity: ≤ 0.17 W/m·K

- Total Mass Loss: ≤ 1.0%

- Collected Volatile Condensable Material: ≤ 0.1%

- Width: Approx. 58–60 inches (147–152 cm)

- Shrinkage Rate: ≤ 5%

Polyester Spiral Dryer Fabric

High-performance polyester spiral dryer fabric designed for industrial drying applications, including papermaking, textile drying, and food processing. Made from 100% polyester monofilament yarns, it features a durable spiral loop structure with cross-wire connections for enhanced stability and air permeability.

Specifications:- Loop Type: Large Loop

- Width: 2400 mm (±1%)

- Length:

- Blue: 150 meters

- White: 150 meters

- Red: 100 meters

- Color Options: Blue, White, Red

- Thickness: Estimated 1.5 – 2.5 mm (Varies by loop size & yarn diameter)

- Weight: Estimated 800 – 1500 g/m² (Depends on weave density)

- Air Permeability: Estimated 800 – 2000 CFM (Varies by loop size & structure)

- Tensile Strength: Estimated 3000 – 6000 N/5 cm (Depends on yarn diameter & weave)

- Working Temperature:

- Continuous: -40°C to +150°C

- Peak: -60°C to +180°C

- pH Range: Optimal: 2-12 | Short-term: 1-13

- Seam Type: Endless spiral seam

- Edge Treatment: Heat-sealed edges to prevent fraying; side-edge sealing machine available.

Polyester Mesh Belt for Textiles - Detailed Specification

Polyester Mesh Belts Specifications for Textile Industry

This specification outlines the technical details for a high-performance polyester mesh belt, specifically designed for textile processing applications, including but not limited to drying, curing, and conveying. The belt is constructed from durable 100% polyester monofilament yarns, woven or knitted to create a stable and permeable mesh structure.

- Width: 42 inches (approximately 1067 mm)

- Length: 15 feet 3 inches (approximately 4648 mm)

- Thickness: ≤ 0.15 mm

- Specific Length and width tolerances: +/- 1%

- Material: 100% Polyester

- Yarn Type: Monofilament

- Weave/Knit Type: (weave or knit type, e.g., plain weave, spiral weave, knitted)

- Mesh Design: 15-20 mesh/cm²

- Open Area: (Specify percentage if applicable, e.g., 40%, 60%)

- Weight: ≤ 12 gms/m²

- Tensile Strength: > 50 N/cm

- Burst Strength: 1.0 Kgf/cm² (approx.)

- Shrinkage: ≤ 5%

- Thermal Conductivity: ≤ 0.17 W/m·K

- Total Mass Loss: ≤ 1.0%

Collected Volatile Condensable Material: ≤ 0.1%

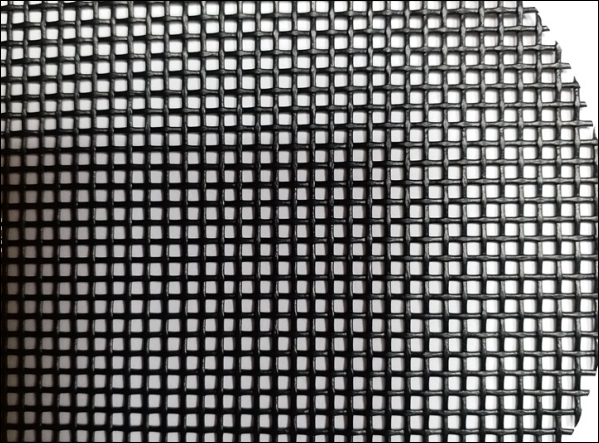

PVC Coated Polyester Mesh Fabric for Tarps and Mesh Applications

This fabric is constructed from 100% polyester yarn, coated with a durable, UV-resistant PVC layer. The mesh structure provides airflow while the PVC coating offers weather protection and strength.

PVC Coated Polyester Screen Mesh for Tarps and Applications

- Material: 100% Polyester yarn, PVC coated

- Yarn Count: 1000 Denier

- Mesh Size: 11 x 11 threads per inch

- GSM (Grams per Square Meter) of Mesh: 350

- Composition Ratio: 30% Polyester, 70% PVC

- Coating Type: PVC, UV-resistant

- Roll Width: 2.50 meters

- Color: Black

More and more -New Product Information and Specifications

- Polyester Monofilament Plain Weave Mesh Fabric for Southeast Asian Market

- PVC-Coated Polyester Mesh Fabric – 500 GSM, Flame-Retardant, Available in Green and Blue

- Printing Screen Mesh – 100% Polyester and 100% Nylon Bolting Cloth

- Endless Woven Polyester Filter Belt (0.71m x 0.22m) with Glued Edges

- Anti-Static Polyester Mesh Belt Reinforced with Metal Fibers

- Polyester Spiral and Woven Mesh Belts for Fabric Drying Applications