Polyester Forming Fabrics: Weave Types, Specifications, And Dimensions

Pertter Polyester Mesh Fabric Co. is a manufacturer and exporter specializing in polyester fabric textiles, offering a wide range of polyester forming fabrics designed to meet the diverse requirements of the paper industry. These fabrics are essential in the papermaking process, particularly during the sheet formation stage, where they ensure optimal drainage, fiber retention, and consistent runnability. These key factors contribute to the overall efficiency and quality of paper production. Manufactured with high-quality polyester monofilaments and multifilaments, Pertter's polyester forming fabrics are engineered to accommodate various paper grades and machine types, ensuring excellent finished products.

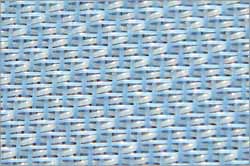

Polyester forming fabric refers to fabrics made from polyester fibers woven using spiral and heddle inserting techniques. These fabrics are used in a range of industries, including paper production, corrugated paper, train ticket paper, as well as filtration and separation applications in environmental protection, pharmaceuticals, mining, metallurgy, machinery, aerospace, and more.

Weaving and Fabric Types

Polyester forming fabrics can be classified based on the weaving method used and the number of sheds in the weave. Common classifications include:

- 4-shed

- 5-shed

- 7-shed

- 8-shed

- 16-shed

- 24-shed

These fabrics are also categorized based on their layers:

- Single-layer fabrics

- Double-layer fabrics

- Two-and-a-half-layer fabrics

- Three-layer fabrics

Applications for Specific Fabric Types

- 4-shed Single Layer Fabric: Ideal for producing culture papers, printing papers, and packing papers.

- 5-shed Single Layer Fabric: Suitable for applications involving health, culture, and packing papers.

- 8-shed Single Layer Fabric: Best used for high-basis weight corrugated papers and packing papers.

- 16-shed Double and a Half Layer Fabric: Designed for making high-quality printing paper, tissue paper, and for processing surface pulp, inner pulp, and base pulp of board paper.

- Multi-shed Three-Layer Fabric: Typically used for producing premium printing papers, tissue papers, and cigarette papers.

Common Specifications and Dimensions

- Mesh Count: 20 mesh to 80 mesh is typical for polyester forming fabrics, with variations depending on the paper being produced. Lower mesh counts are suitable for high-drainage papers, while higher mesh counts are used for fine paper production.

- Yarn Diameter: 100 µm to 500 µm: The yarn diameter affects the fabric's strength, drainage capacity, and fiber support. Fabrics with larger yarn diameters are more durable, while finer yarns are better for drainage and retaining fine fibers.

- Fabric Thickness: 0.4 mm to 2.5 mm: The fabric's thickness is crucial in determining its drainage capacity and runnability. Thicker fabrics offer better drainage and fiber retention, whereas thinner fabrics are often used for more delicate applications.

- Width: Fabrics are available in various widths, commonly ranging from 1 meter (m) to 10 meters (m). Custom widths can be provided to match the specific dimensions of the paper machine.

- Length: Polyester forming fabrics are generally supplied in rolls, with standard lengths ranging from 50 meters (m) to 100 meters (m), depending on customer requirements.

|

|

|

|

| Four-Shed Single Layer Forming Screen | Five-Shed Single Layer Forming Screen |

|

|

|

|

| Eight-Shed Single Layer Forming Screen | Seven-Shed Double Layer Forming Screen |

|

|

|

|

| Eight-Shed Double and A Half Layer Screen | Sixteen-Shed Double and A Half Layer Screen |

Polyester Forming Screen Series Products Data

| Weaving Series and Types | Thread Diameter mm |

Density (pieces /cm) |

Strength (N/cm) |

Thick- ness mm |

Air Perm -eation m3/m2h |

Max. Elongation at 50N/cm |

|||

| Warp | Weft | Warp | Weft | Mesh Surface | Inserting Place | ||||

| Four-Shed Single Layer Forming Screen | 0.20 | 0.25 | 30 | 22 | =600 | =400 | 0.49 | 8000 | 0.60 % |

| 0.20 | 0.25 | 30 | 23 | =600 | =400 | 0.495 | 7500 | 0.60 % | |

| 0.20 | 0.25 | 30 | 24 | =600 | =400 | 0.50 | 7000 | 0.60 % | |

| 0.20 | 0.27 | 30 | 21.5 | =600 | =400 | 0.51 | 7800 | 0.60 % | |

| 0.20 | 0.27 | 30 | 22.5 | =600 | =380 | 0.515 | 7300 | 0.60 % | |

| 0.18 | 0.20 | 35 | 28 | =600 | =380 | 0.43 | 7500 | 0.68 % | |

| 0.18 | 0.20 | 35 | 30 | =600 | =380 | 0.43 | 7000 | 0.68 % | |

| 0.18 | 0.20 | 35 | 30.5 | =600 | =380 | 0.43 | 6500 | 0.68 % | |

| Five-Shed Single Layer Forming Screen | 0.20 | 0.20 | 30 | 27.5 | =600 | =400 | 0.46 | 6800 | 0.60 % |

| 0.17 | 0.20 | 32 | 28.5 | =500 | =350 | 0.41 | 7100 | 0.60 % | |

| 0.17 | 0.17 | 32 | 29.5 | =500 | =350 | 0.39 | 6600 | 0.60 % | |

| 0.20 | 0.21 | 35 | 32 | =600 | =400 | 0.48 | 7000 | 0.60 % | |

| Eight-Shed Single Layer Forming Screen | 0.22 | 0.35 | 28 | 19.5 | =700 | =500 | 0.85 | 9000 | 0.65 % |

| 0.22 | 0.38 | 29.5 | 19 | =700 | =500 | 0.87 | 8500 | 0.65 % | |

| 0.22 | 0.35 | 29 | 20 | =700 | =500 | 0.85 | 8500 | 0.65 % | |

| 0.22 | 0.38 | 31.5 | 19 | =700 | =500 | 0.87 | 8000 | 0.65 % | |

| Seven-Shed Single Layer Forming Screen | 0.20 | 0.20 / 0.22 0.22 (t66) |

54.7 | 36.6 | =800 | =600 | 0.71 | 5800 | 0.60 % |

| 0.17 | 0.17 / 0.20 0.20 (t66) |

60 | 48 | =800 | =600 | 0.635 | 5200 | 0.60 % | |

| 0.17 | 0.17 / 0.22 0.22 (t66) |

65.7 | 49.6 | =800 | =600 | 0.635 | 4550 | 0.60 % | |

| 0.15 | 0.17 / 0.17 0.17 (t66) |

70 | 50 | =800 | =600 | 0.59 | 5200 | 0.60 % | |

| Eight-Shed Double Layer Forming Screen | 0.17 | 0.18 / 0.20 0.20 (t66) |

61.3 | 51.2 | =850 | =600 | 0.65 | 5700 | 0.60 % |

| 0.18 | 0.19 / 0.20 0.20 (t66) |

66 | 49 | =900 | =650 | 0.68 | 4750 | 0.60 % | |

| 0.15 | 0.16 / 0.19 0.19 (t66) |

70.5 | 50.5 | =900 | =650 | 0.60 | 6200 | 0.60 % | |

Eight-Shed and Sixteen-Shed Double and A Half Layer Screen Data

| Model of Fabric | Thread Diameter mm | Density/cm | Air Permeation m3/m2h |

||

| Warp | Weft (Up/Lower) | Warp | Weft | ||

| 2B3316 | 0.28 | 0.20,0.27/0.40,0.40 | 37~38 | 40~41 | 6000 |

| 2B3316-1 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 37~38 | 6000 |

| 2B3316-2 | 0.28 | 0.20,0.27/0.45,0.45 | 37~38 | 31~32 | 8000 |

| 2B5008 | 0.17 | 0.13,0.18/0.32,0.32 | 55~56 | 48~49 | 6500 |

| 2B5216 | 0.17 | 0.17,0.22/0.27,0.27 | 57.5~58.5 | 50~51 | 5300 |

| 2B5216-1 | 0.17 | 0.19,0.22/0.35,0.35 | 57.5~58.5 | 43.5~44.5 | 6200 |

| 2B5408 | 0.17 | 0.13,0.20/0.35,0.35 | 59~60 | 43~44 | 6300 |

| 2B5416 | 0.17 | 0.13,0.20/0.35,0.35 | 59.5~60.5 | 42~43 | 6000 |

| 2B5608 | 0.17 | 0.13,0.18/0.22,0.22 | 61~62 | 52~53 | 5700 |

| 2B5608-1 | 0.17 | 0.13,0.20/0.25,0.25 | 60~61 | 54~55 | 5600 |

| 2B5608-2 | 0.17 | 0.13,0.20/0.32,0.32 | 60~61 | 48~49 | 6000 |

| 2B5608-3 | 0.17 | 0.13,0.20/0.35,0.35 | 60~61 | 47~48 | 5600 |

| 2B5608-4 | 0.17 | 0.13,0.20/0.32,0.32 | 61.5~62.5 | 55.5~56.5 | 6900 |

| 2B5608-5 | 0.18 | 0.13,0.18/0.22,0.22 | 62~63 | 53~54 | 6800 |

| 2B5608-6 | 0.18 | 0.13,0.20/0.25,0.25 | 61~62 | 61~62 | 5940 |

| 2B5608-7 | 0.15 | 0.13,0.18/0.25,0.25 | 62~63 | 53~54 | 6600 |

| 2B5608-8 | 0.15 | 0.13,0.18/0.32,0.32 | 61~62 | 56~57 | 6400 |

| 2B5608-9 | 0.17 | 0.13,0.18/0.35,0.35 | 61~62 | 51~52 | 6900 |

| 2B5608-10 | 0.17 | 0.13,0.22/0.35,0.35 | 61.5~62.5 | 48.5~49.5 | 5800 |

| 2B5808 | 0.17 | 0.13,0.18/0.22,0.22 | 63~64 | 53~54 | 6500 |

| 2B5808-1 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 54~55 | 5000 |

| 2B5808-2 | 0.17 | 0.13,0.20/0.25,0.25 | 63~64 | 51.5~52.5 | 5100 |

| 2B6208 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 56.5~57.5 | 5500 |

| 2B6208-1 | 0.17 | 0.13,0.18/0.20,0.20 | 68~69 | 54.5~55.5 | 6000 |

| 2B6208-2 | 0.17 | 0.13,0.18/0.23,0.23 | 63~64 | 51.5~52.5 | 5100 |

| 2B6216 | 0.17 | 0.13,0.18/0.23,0.23 | 68~69 | 61.5~62.5 | 5600 |

| 2B6216-1 | 0.17 | 0.13,0.20/0.25,0.25 | 68~69 | 64.5~65.5 | 6400 |

| 2B6216-2 | 0.17 | 0.13,0.18/0.25,0.25 | 68~69 | 51.5~52.5 | 5400 |

| 2B6216-3 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 52.5~53.5 | 5500 |

| 2B6216-4 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 49.5~50.5 | 8000 |

| 2B6216-5 | 0.17 | 0.13,0.20/0.35,0.35 | 68~69 | 46.5~47.5 | 7000 |

| 2B6408 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 57~58 | 6200 |

| 2B6408-1 | 0.17 | 0.12,0.18/0.20,0.20 | 70~71 | 65~66 | 6500 |

Single-Layer Polyester Forming Mesh Fabrics For Papermaking

Single-layer forming fabrics, with their simple structure, cater to general papermaking forming needs.

Single-Layer Two-Shed (One-Over-One-Under):

- Applications: Primarily used in sewage treatment plants and sludge dewatering machines.

- Characteristics: Simple structure, high fiber support index, square mesh openings, excellent dewatering performance, and easy paper threading.

- Advantages: Good retention and strong drainage.

Single-Layer Three-Shed (One-Over-Two-Under):

- Applications: Used in sludge dewatering machines, pulp washers, and bleaching machines.

- Characteristics: Simple structure, high paper sheet support, good air permeability, and excellent drainage.

- Advantages: Excellent dewatering, wear resistance, and easy cleaning.

Single-Layer Four-Shed (One-Over-Three-Under):

- Applications: Suitable for various paper machines.

- Characteristics: Simple structure, with warp-dominated weaving.

- Advantages: Excellent dewatering, controlled wire marks on the paper surface, and moderate retention.

Single-Layer Five-Shed (One-Over-Four-Under):

- Applications: Widely used in the production of writing paper, printing paper, kraft paper, newsprint, tissue paper, and other papers requiring high dewatering performance.

- Characteristics: Simple structure, wear-resistant fabric surface on the table roll side, and uniform mesh openings.

- Advantages: Better dewatering performance than four-shed fabrics, high fiber support index, good retention, easy paper threading, and long service life.

Single-Layer Eight-Shed:

- Applications: Primarily used in the production of high basis weight paper and paperboard.

- Characteristics: Wear-resistant fabric surface on the table roll side, and uniform mesh openings.

- Advantages: Improved dewatering compared to five-shed fabrics, and long service life.

Polyester forming fabrics are indispensable components in the paper industry and many other sectors. Their versatility, durability, and performance make them suitable for a wide range of applications. Proper selection and maintenance of these fabrics are crucial for achieving optimal results in papermaking and other industrial processes.

Applications of Polyester Forming Fabrics

Polyester forming fabrics serve diverse functions across various industries, primarily in papermaking, filtration, and separation.

Papermaking:

- Sheet Formation: Supports pulp slurry, enabling water drainage and fiber retention, thus influencing paper smoothness, porosity, and strength.

- Dewatering: Facilitates efficient water removal, boosting productivity.

- Fiber Retention: Retains fibers, reducing waste and improving paper quality.

- Runnability: Ensures smooth machine operation, minimizing wear and contamination.

Filtration and Separation:

- Environmental Protection: Wastewater treatment and sludge filtration.

- Pharmaceuticals: Product purification through filtration.

- Mining and Metallurgy: Mineral, ore, and metal separation.

Other Industrial Applications:

- Corrugated Paper & Packaging: Production of high-basis weight papers.

- Textile Industry: Dewatering textile slurries.

- Aerospace: Filtration in composite material production.

- Food & Beverage: Liquid filtration (juices, oils).

- Cigarette Paper: Precise fiber retention and drainage.

- General Industrial: Printing/tissue paper manufacturing, pulp mills.