Polyester Dryer Fabric-High- Polyester Dryer Mesh Conveyor Belt for Food

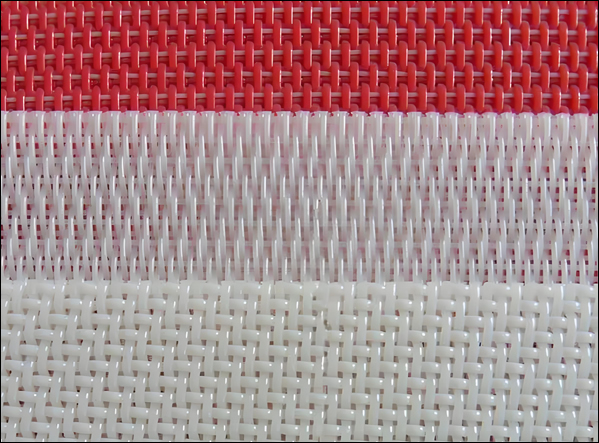

Polyester dryer fabric is a specialized industrial fabric designed for efficient solid/liquid separation and sludge dewatering. It is primarily used in vacuum and multi-roll belt presses, as well as in paper drying processes. The fabric undergoes precise heat-setting under controlled temperature and tension conditions to ensure maximum operational stability. With its unique spiral weave patterns, it offers rapid drainage and excellent cake release, making it an ideal choice for various industrial applications.

Classification

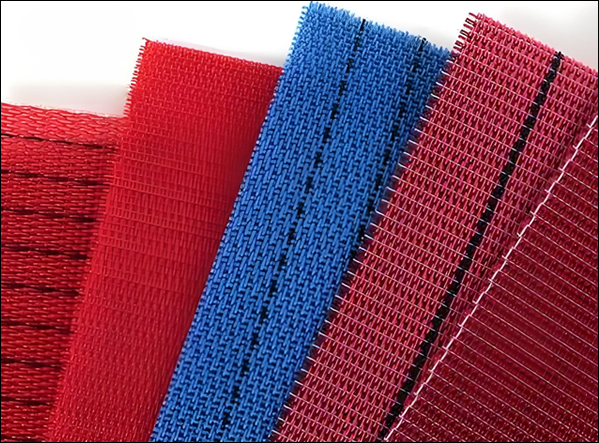

Polyester dryer fabric can be categorized based on weaving patterns, mesh structure, and connection types:

By Weaving Pattern:

- Three-shed weave: This weave pattern provides a balance of strength, stability, and permeability, making it suitable for a wide range of drying applications, particularly for lighter papers under 70 grams. It is often used in one-and-a-half-layer configurations.

- Four-shed weave: Offering enhanced stability and durability, this weave is ideal for heavier applications and demanding drying conditions, especially for papers weighing more than 70 grams. It is commonly used in double-layer constructions.

By Mesh Structure:

- Single-layer: This lightweight and cost-effective construction is suitable for applications where basic drying performance is required.

- One-and-a-half-layer: This configuration, often employing a three-shed weave, offers improved stability and runnability compared to single-layer fabrics, providing a balance of performance and cost for lighter papers.

- Double-layer: Typically utilizing a four-shed weave, this construction provides the highest level of stability, durability, and performance, ideal for demanding applications, heavier papers, and high-speed drying processes.

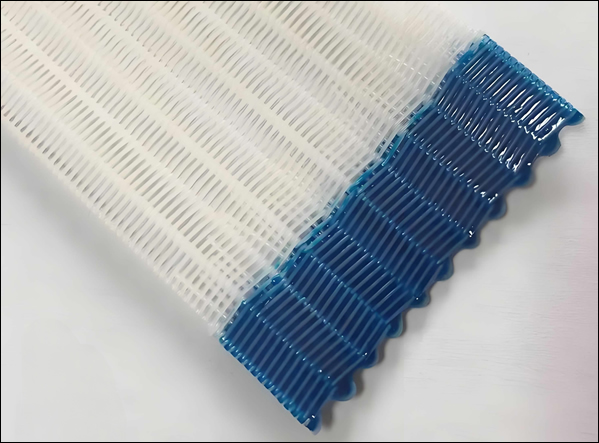

- Flat dryer mesh: This structure provides a smooth and uniform drying surface, improving paper quality and minimizing surface imperfections. It is particularly beneficial for applications requiring a high-quality finish.

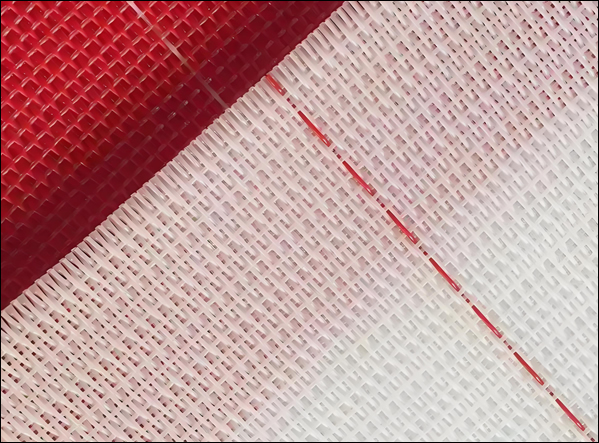

By Connection Type:

- Inserting Type

- Slotting Type

- Slotting Ring Type

- Spiral Ring Connecting Type

By Specific Applications:

- 4106 Round Thread Screen: Suitable for thin paper with a weight under 60 grams.

- Flat Thread Screen: Designed for specialized drying applications requiring smooth texture and high stability.

Polyester Dryer Fabric for Paper & Board Drying

Polyester Dryer Fabric for Paper and Board Manufacturing

Paper Drying Polyester Mesh Machine

Polyester Dryer Fabric Conveyor Belt for Food Processing

Polyester Dry Mesh Belt for Filter Press Sludge Dewatering

Polyester Dryer Fabric Specifications

- Widths: 1000-6000 mm (39.4-236.2 inches)

- Roll Lengths: 50-500 meters (164-1640 feet)

- Material: 100% heat-set polyester

- Thread Types: Round, Flat

Material Composition:

- 100% polyester: Polyester offers excellent heat resistance, dimensional stability, and chemical resistance, making it ideal for demanding drying environments.

- Heat-set stability: The fabric undergoes a heat-setting process to enhance its dimensional stability and prevent shrinkage or deformation during operation.

Mesh Sizes:

- Fine: 15-50 mesh (0.6-2 threads/mm)

- Medium: 60-150 mesh (2.4-6 threads/mm)

- Coarse: 160-300 mesh (6.3-12 threads/mm)

Packaging:

- Standard: Cardboard cores, plastic film

- Custom: Vacuum seal, crates, labeling

Performance

- Air Permeability: 150 - 1200 CFM or 2000 - 16000 l/m²/s

- Tensile Strength: 200 - 1200 N/cm

- Elongation: 5% - 35%

- Temperature Resistance: Up to 180°C (356°F)

- Chemical Resistance: High (resistant to most industrial chemicals and solvents)

Characteristics

Polyester dryer fabric offers several advantages, making it a preferred choice in paper drying, sludge dewatering, and filtration processes:

- High Dimensional Stability: Heat-set processing ensures precise stability under high tension.

- Excellent Drainage and Cake Release: Unique spiral weave patterns facilitate quick water removal and efficient cake release.

- Durability and Longevity: Resistant to wear and tear, extending operational lifespan.

- Chemical and Heat Resistance: Withstands harsh industrial conditions, including exposure to chemicals and high temperatures.

- Optimized for Different Paper Weights: Suitable for drying paper of varying thickness, from thin to heavy sheets.

- Versatile Connection Types: Different connection methods enhance adaptability in various drying and filtration applications.

Weaving Series and Types |

Thread Diameter mm |

Density (pieces/cm) |

Strength (N/cm) |

Weight kg/m2 |

Thick-ness |

Air |

||||

Warp |

Weft |

Warp |

Weft |

Mesh Surf-ace |

Inser-ting Place |

Spiral Conne-cting |

||||

Three-Shed Series |

0.50 |

0.50 |

24 |

12 |

2000 |

1400 |

900 |

1.06 |

1.9 |

8000 |

0.45 |

0.45 |

24 |

13 |

2000 |

1400 |

900 |

0.99 |

1.7 |

8500 |

|

0.50 |

0.50 |

25 |

12 |

2000 |

1400 |

900 |

1.10 |

1.9 |

7000 |

|

0.45 |

0.45 |

25 |

13 |

2000 |

1400 |

900 |

1.02 |

1.8 |

6700 |

|

Four-Shed Series |

0.5 |

0.5 |

22 |

12 |

2000 |

1300 |

850 |

1.15 |

2.0 |

15000 |

0.5 |

0.5 |

24 |

12 |

2000 |

1400 |

900 |

1.26 |

2.1 |

12000 |

|

0.5 |

0.5 |

26 |

12 |

2100 |

1500 |

950 |

1.3 |

2.1 |

11000 |

|

0.5 |

0.5 |

20 |

11 |

1800 |

1200 |

800 |

0.85 |

2.0 |

8000 |

|

Round Thread Screen |

0.5 |

0.70 | 22.8 |

12.4 |

2200 |

1500 |

900 |

1.3 |

1.75 |

6800 |

| 0.30 | ||||||||||

Flat Thread Screen |

0.58 0.37 |

0.35 0.68 |

21 |

15 |

2000 |

1400 |

800 |

1.2 |

1.50 |

2500 |

| 0.58 0.37 |

0.35 0.68 |

21 |

14 |

2000 |

1400 |

800 |

1.2 |

1.5 |

3000 |

|

| 0.58 0.37 |

0.35 0.68 |

21 |

13 |

2000 |

1400 |

800 |

1.2 |

1.5 |

4000 |

|

| 0.58 0.37 |

0.35 0.68 |

21 |

13.5 |

2000 |

1400 |

800 |

1.2 |

1.48 |

3500 |

|