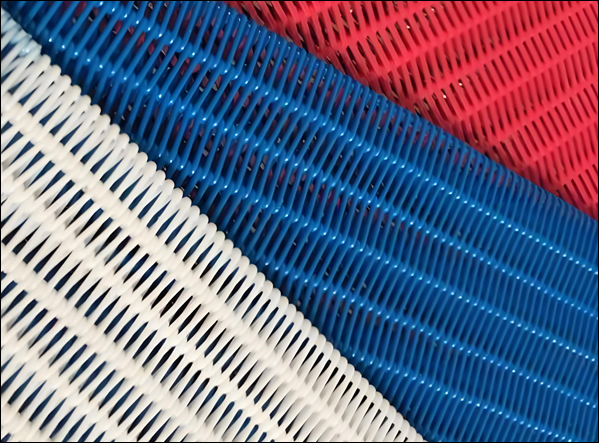

Ployester Spiral Dryer Mesh Fabric for Papermaking and Textile Dyeing

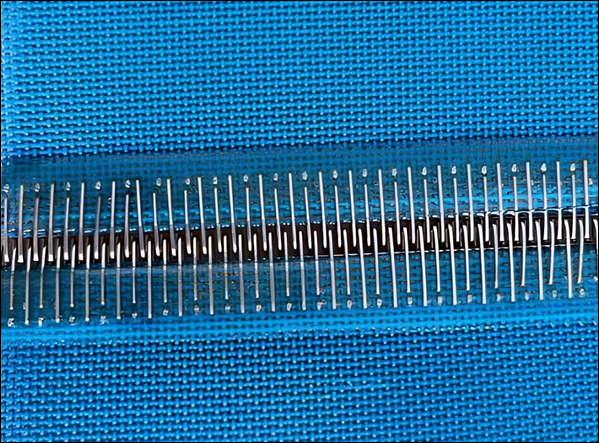

Polyester Spiral Dryer Mesh is a high-performance industrial fabric. It is constructed from polyester monofilament yarns formed into spiral loops, which are then connected by weft yarns to create a spiral mesh. The fabric is known for its smooth surface, excellent air permeability, and high-temperature resistance. It features an integrated seam and is widely used in industries such as papermaking, food processing, textile printing and dyeing, and pharmaceuticals. Polyester spiral dry screen is mainly used in the dryness part of paper-making machines, drying process of printing and dyeing and other industrials.

Polyester Spiral Woven Dryer Mesh Screen

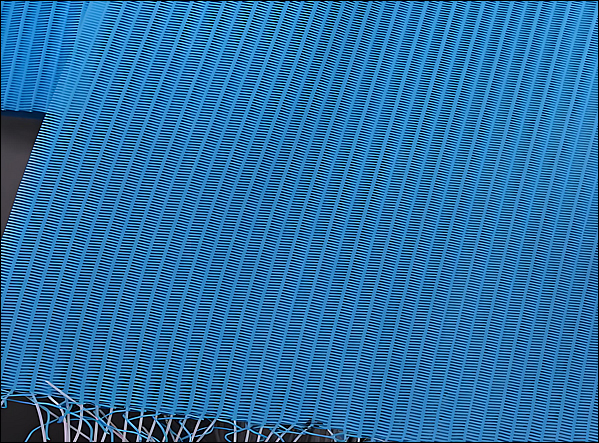

Super Loop Industrial Spiral Polyester Mesh Screen for Drying Applications

Medium Loop High-Performance Polyester Spiral Dryer Fabric

Polyester Filter Press Fbric:

This kind of polyester mesh belt is made of polyester spiral dryer fabric which is filled with stuff to reduce the air permeation and to intensitive the opening, hence to reduce the material loss from the mesh opening. Polyester spiral filter screen is mainly used in sludge desiccation, paper pulp washing, coal washing, chemicals, dehydration of wine bran, vinegar bran dehydration and other industries. It is better in the high ventilation part of the dryness part of paper-making machin.

General Specifications

- Spiral Loop Width: Ranges from 5.2 mm to 12.3 mm.

- Monofilament Diameter: Ranges from 0.50 mm to 1.20 mm.

- Tensile Strength: Ranges from 1800 N/cm to 2600 N/cm.

- Weight: Ranges from 1.0 g/cm² to 2.35 g/cm².

- Thickness: Ranges from 1.0 mm to 2.35 mm.

- Air Permeability: Ranges from 15000 to 22000 CFM.

Applications

- Papermaking Industry: Used for paper drying, particularly for high-grammage packaging paper, cultural paper, paperboard, and pulp board.

- Food Processing Industry: Used for food drying, such as fruits and vegetables.

- Textile Printing and Dyeing Industry: Used for drying printed and dyed textiles.

- Pharmaceutical Industry: Used for drying pharmaceutical products.

- Rubber Products Industry: Used for drying rubber products.

Polyester Spiral Dryer Mesh Fabric Type

Super Loop

- Spiral Loop Width: 10 mm

- Spiral Ring Monofilament: 0.90 mm

- Connection Wire: 1.10 mm

- Tensile Strength: 2300 N/cm

- Weight: 1.64 kg/m²

- Thickness: 3.03 mm

- Air Permeability: 20000 m³/m²/h (1250 CFM 127/pa)

Large Loop

- Spiral Loop Width: 8 mm

- Spiral Ring Monofilament: 0.68 mm

- Connection Wire: 0.90 mm

- Tensile Strength: 2000 N/cm

- Weight: 1.31 kg/m²

- Thickness: 2.45 mm

- Air Permeability: 18000 m³/m²/h (1125 CFM 127/pa)

Medium Loop

- Spiral Loop Width: 7.2 mm

- Spiral Ring Monofilament: 0.68 mm

- Connection Wire: 0.90 mm

- Tensile Strength: 2000 N/cm

- Weight: 1.40 kg/m²

- Thickness: 2.45 mm

- Air Permeability: 16000 m³/m²/h (1000 CFM 127/pa)

Small Loop

- Spiral Loop Width: 5.2 mm

- Spiral Ring Monofilament: 0.50 mm

- Connection Wire: 0.80 mm

- Tensile Strength: 1800 N/cm

- Weight: 1.00 kg/m²

- Thickness: 1.87 mm

- Air Permeability: 15000 m³/m²/h (937 CFM 127/pa)

| Model | Thread Diameter (mm) | Thickness(mm) | Weight(kg/m2) | Air Permeability (m3/m2h) |

|

| Warp | Weft | ||||

| 4070B | 0.9 | 1.1 | 3 | 1.7 | 20500+-1500 |

| 4070A | 0.9 | 1.1 | 3 | 1.9 | 5250+-500 |

| 3868B | 0.7 | 0.9 | 2.5 | 1.4 | 18500+-1500 |

| 3868A | 0.7 | 0.9 | 2.5 | 1.7 | 4750+-500 |

| 3252B | 0.5 | 0.7 | 1.9 | 1.1 | 15000+-1500 |

| 3252A | 0.5 | 0.7 | 1.9 | 1.4 | 4000+-500 |

BREAKING STRENGTH: |

|

LW4.0x7.0

|

>2300-2800N/cm

|

LW3.8x6.8

|

>2100N/cm

|

LW3.2x5.2

|

>1800-2000N/cm

|