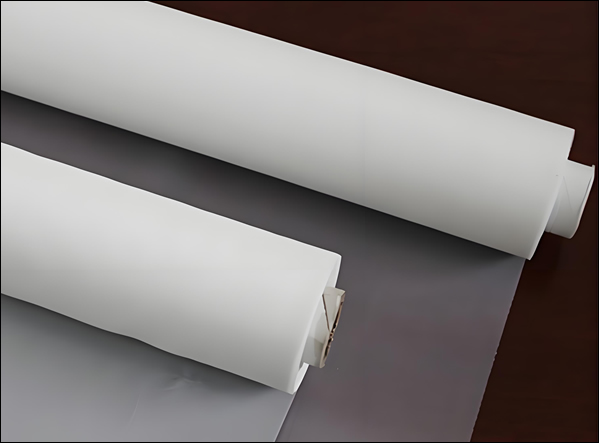

Polyester Mesh Sifting Cloth: Flour Milling Grade

Polyester Sifting Mesh for Flour Milling , specifically designed for flour milling applications, is woven from high-tensile polyester monofilament yarn. Its precise weave structure ensures superior sifting performance, durability, and accurate particle separation. Commonly custom-cut to fit flour milling sifters and filters, this bolting cloth also serves effectively as fine screen printing mesh. The fabric's design prevents plastic deformation, ensuring it maintains proper tension and filtration accuracy.

Flour Milling: Polyester Sifting Mesh Cloth

Flour Milling Mesh Cloth for Sifting and Grading of Flours, Corns and Various Grains

Flour Milling and Food Industry: Polyester Mesh Screen

Product Specifications

- Material: 100% Polyester Monofilament Yarn

- Weaving Pattern: Plain weave

- Mesh Count: 30 mesh to 420 mesh

- Thread Diameter: 0.05 mm to 0.18 mm (0.002 inches to 0.007 inches)

- Mesh Aperture: 20 µm to 600 µm (0.0008 inches to 0.0236 inches)

- Fabric Thickness: 0.05 mm to 0.30 mm (0.002 inches to 0.012 inches)

- Open Area: 20% to 55% (variable by mesh count and thread diameter)

- Roll Widths: 1.0 m, 1.2 m, 1.5 m (39.4 inches, 47.2 inches, 59 inches), custom widths available

- Roll Lengths: 30 m, 50 m, 100 m (98 ft, 164 ft, 328 ft), custom lengths available

- Cut-to-Size: Tailored to specific milling equipment dimensions

- Color Options: White (natural), Yellow, Custom colors available (minimum quantity required)

- Tensile Strength: Warp ≥ 5000 N/m, weft ≥ 3000 N/m. Ensures consistent tension, prevents deformation.

- Dimensional Stability: Elongation < 1% at specified loads. Maintains uniform aperture dimensions.

- Chemical Resistance: Tolerates pH 2-12. Resists common milling solvents and cleaning agents.

- Abrasion Resistance: Withstands > 10,000 abrasion cycles. Extends service life.

- Temperature Tolerance: -40°C to +100°C. Maintains integrity in milling temperatures.

- Aperture Accuracy: Aperture variation ± 5 µm. Thread diameter variation ± 2 µm. Ensures uniform particle separation.

- Cleanability: Smooth surface. Resists residue buildup, facilitates easy cleaning.

Types

- Plansifter Screens: These screens play a critical role in flour milling operations, extensively utilizing polyester mesh. Various mesh sizes are selected depending on specific sifting stages within the plansifter.

- Purifier Covers: These covers separate bran, endosperm, and other grain components. Specialized polyester mesh fabrics, often called 'grit gauze,' are particularly suitable for purifier machines.

- Centrifugal Sifters: Polyester mesh is similarly utilized within centrifugal sifting equipment.

- Grading: Polyester mesh is used extensively to grade flour into accurately defined particle sizes.

Performance

- Precise Sifting: Ensures accurate particle separation for consistent flour quality.

- Durability: Long service life due to high-quality materials and weaving.

- Reliability: Maintains consistent performance over time.

- Ease of Use: Easy to install and maintain.

Applications

- Flour Milling: Roller mills, purifiers, sifters.

- Food Industry: Fine sifting and grading.

- Industrial Filtration: Chemical, pharmaceutical, wastewater treatment.

- Screen Printing: Precision printing mesh.

Comparison of Polyester, Nylon (Polyamide), and Silk for Flour Milling Mesh Screen

Material:

- Polyester: Durable synthetic monofilament, stable, widely used in industrial flour milling.

- Nylon (Polyamide): Elastic and strong synthetic monofilament, flexible under tension.

- Silk: Natural fiber, historically used, largely replaced due to lower durability.

Tensile Strength:

- Polyester: 42–60 kg/mm² (High)

- Nylon: 40–50 kg/mm² (Good)

- Silk: 30–38 kg/mm² (Low)

Elongation:

- Polyester: 15–30% (Moderate)

- Nylon: 25–45% (High)

- Silk: 15–25% (Low)

Resiliency (3% elongation):

- Polyester: 90–95% (Excellent)

- Nylon: 95–100% (Very High)

- Silk: 70–80% (Moderate)

Temperature Resistance:

- Polyester: -40°C to +150°C (Excellent)

- Nylon: -40°C to +130°C (Good)

- Silk: -40°C to +110°C (Low)

Water Absorption (65% RH, 20°C):

- Polyester: 0.4–0.6% (Very Low)

- Nylon: 4–5% (Moderate)

- Silk: 8–10% (High)

Chemical Resistance:

- Polyester: High (pH 2–12)

- Nylon: Moderate (pH 3–11)

- Silk: Low (Limited)

Electrical Resistance (Ω·cm/g):

- Polyester: ~10^16 (Excellent)

- Nylon: ~10^14 (Good)

- Silk: ~10^10 (Low)

For customized specifications or special requests, please contact us directly to discuss your requirements.