Polyester Mesh Fabric for Paper Pulping and Filtration

Polyester Mesh Fabric for Paper Pulping is a high-performance industrial fabric designed to withstand the demanding conditions of pulp production. Made from premium polyester monofilament, it offers exceptional durability, chemical resistance, and mechanical strength. Engineered for high tension and continuous operation, it resists harsh chemicals used in the pulping process, ensuring a long service life. Polyester Mesh Fabric for Paper Pulping is an environmentally friendly, pollution-free solution widely used in the paper-making industry. It is an essential and consumable component in paper production, primarily including polyester molding mesh, polyester dryer mesh, polyester spiral mesh, and polyester press filter mesh. As the name suggests, polyester paper mesh plays a crucial role in various applications across the paper industry, offering a reliable and high-tech solution for modern papermaking.

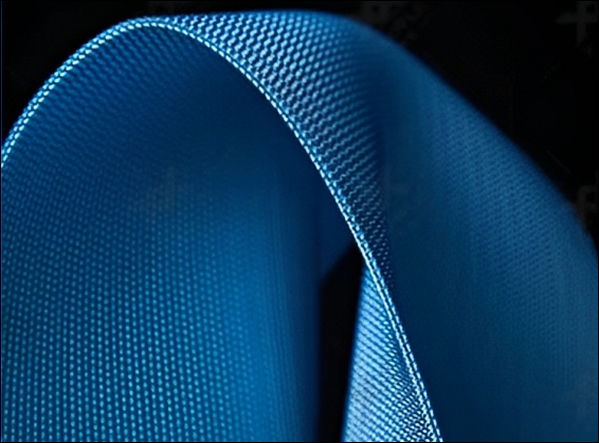

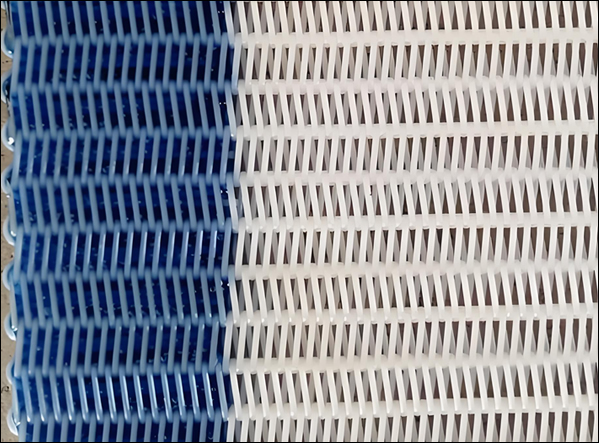

Square Hole Polyester Mesh Fabric for Paper Pulping

Polyester Spiral Dryer Fabric for Pulp Washing

Spiral Polyester Mesh Fabric for Paper Drying Filtration

Material

- 100% Polyester (PET) Monofilament

- Available in Hydrolysis-Resistant (HR) Polyester for high-temperature and humid environments

- Anti-Static & Anti-Adhesion Coatings (optional for reducing clogging and buildup)

Weave Types

- Plain Weave – Provides uniform filtration and good dimensional stability

- Twill Weave – Offers higher strength and better wear resistance

- Satin Weave (Broken Twill or Modified) – Improves dewatering efficiency and smoothness

- Multi-Layer Weave – Enhances durability and filtration precision (commonly used in forming and pressing fabrics)

Mesh size

The typical mesh size of polyester mesh fabric used in paper pulping varies depending on the specific stage of the pulping and papermaking process. The exact mesh size depends on factors such as pulp consistency, drainage requirements, and machine specifications. Higher mesh counts (finer mesh) provide better filtration, while lower mesh counts (coarser mesh) allow for faster drainage and higher throughput.

- Forming Fabric: 30 to 100 mesh

- Pressing Fabric: 20 to 60 mesh

- Dryer Fabric: 20 to 80 mesh

- Pulp Washing & Filtering: 40 to 200 mesh

Thread Diameter

The thread diameter of polyester mesh fabric used in paper pulping varies depending on the mesh size and application. The specific thread diameter is selected based on the required strength, permeability, and durability of the fabric in the pulping process. Finer diameters improve filtration accuracy, while thicker threads enhance durability and stability.

- Forming Fabric: 0.10 – 0.40 mm

- Pressing Fabric: 0.15 – 0.50 mm

- Dryer Fabric: 0.20 – 0.60 mm

- Pulp Washing & Filtering: 0.08 – 0.30 mm

Fabric Thickness

The appropriate thickness is selected based on factors such as drainage efficiency, mechanical strength, and resistance to wear. Thicker fabrics provide better durability, while thinner ones offer improved permeability and dewatering performance.

- Forming Fabric: 0.50 – 2.50 mm

- Pressing Fabric: 1.50 – 4.50 mm

- Dryer Fabric: 1.00 – 3.50 mm

- Pulp Washing & Filtering: 0.30 – 2.00 mm

Open Area (%)

- Forming Fabric: 15 – 35%

- Pressing Fabric: 8 – 25%

- Dryer Fabric: 5 – 20%

- Pulp Washing & Filtering: 10 – 40%

- Note: A higher open area improves drainage and dewatering efficiency.

Air Permeability (m³/m²·h or CFM)

- Forming Fabric: 2000 – 8000 m³/m²·h

- Pressing Fabric: 500 – 3000 m³/m²·h

- Dryer Fabric: 200 – 1500 m³/m²·h

- Pulp Washing & Filtering: 500 – 7000 m³/m²·h

- Note: Air permeability affects water drainage, drying efficiency, and sheet formation quality.

Tensile Strength (N/cm or MPa)

- Warp Direction (MD): > 250 – 1500 N/cm

- Weft Direction (CD): > 150 – 1200 N/cm

- Note: Tensile strength depends on fabric thickness, thread diameter, and weaving structure.

Density (Threads/cm)

- Forming Fabric: 20 – 60 threads/cm

- Pressing Fabric: 10 – 40 threads/cm

- Dryer Fabric: 5 – 30 threads/cm

- Pulp Washing & Filtering: 15 – 80 threads/cm

- Note: Higher thread density improves dimensional stability and filtering precision.

Roll Dimensions

- Width: 0.5 – 10 meters (customizable)

- Length: 20 – 100 meters per roll (or as required)

- Note: Rolls are produced according to customer requirements for machine compatibility

Available Colors

- Blue (Most common for easy contamination detection)

- White (Standard industrial use)

- Green (Enhanced UV resistance for outdoor exposure)

- Yellow (Customized for visibility and tracking)

- Black (Optional for high-wear applications)

Applications

- Paper Pulping – Used in pulp washing, dewatering, and screening

- Paper Forming & Pressing – Enhances drainage and fiber retention

- Dryer Section – Facilitates moisture removal and prevents sticking

- Pulp Mills & Paper Recycling Plants – For filtering and fiber separation

- Industrial Filtration – Used in chemical processing, wastewater treatment, and food-grade applications

Features:

- High Tensile Strength & Durability – Withstands high tension and continuous operation

- Excellent Chemical & Hydrolysis Resistance – Suitable for harsh pulping environments

- Superior Drainage & Dewatering Performance – Ensures efficient water removal

- Abrasion & Wear Resistance – Increases service life in demanding conditions

- Easy Cleaning & Anti-Clogging Design – Reduces maintenance requirements

- Dimensional Stability – Retains shape under varying temperatures and loads

Manufacturing Process:

- Polyester Monofilament Selection – High-quality PET yarn is chosen for durability.

- Weaving – Fabric is woven using plain, twill, satin, or multi-layer weave depending on the application.

- Heat Setting & Stabilization – The fabric undergoes thermal treatment to enhance dimensional stability.

- Surface Treatment (Optional) – Coatings like anti-static, anti-adhesion, or hydrolysis-resistant treatments are applied.

- Cutting & Customization – Rolls are trimmed to required widths and lengths.

- Final Inspection & Quality Control – Each batch undergoes tensile strength, air permeability, and filtration efficiency tests.

Model |

fiber diameter |

density threads/cm |

opening; perforate % |

mesh /inch |

use |

||

|

weft |

warp |

weft |

warp |

|||

PB01 |

0.25 |

0.30 |

17±0.5 |

12±0.5 |

37 |

43 |

used in pulping machine |

PB02 |

0.25 |

0.27 |

19.5±0.5 |

11±0.5 |

36 |

50 |

|

PB03 |

0.25 |

0.30 |

17±0.5 |

12±0.5 |

33 |

43 |

|

PB04 |

0.27 Or 0.30 |

0.35 |

17±0.5 |

11±0.5 |

33 |

43 |

|

PB05 |

0.25 |

0.27 |

19.5±0.5 |

11±0.5 |

36 |

50 |

|

PB06 |

0.25 |

0.30 |

19.5±0.5 |

11±0.5 |

33 |

50 |

|