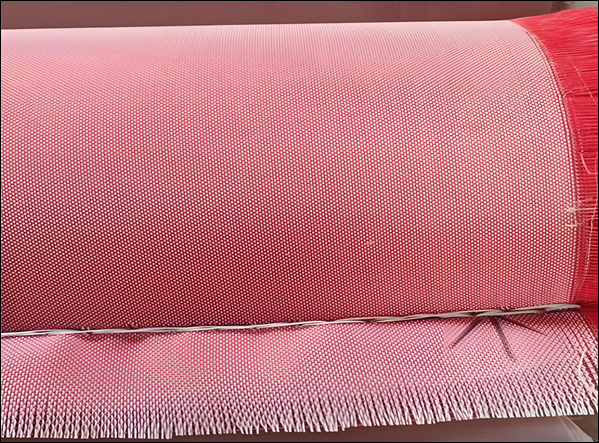

Anti-static Polyester Screen Mesh

Petter manufactures Anti-static polyester mesh made with monofilament in spiral weaving. It can be made with filling flat wire or round wire to increase ventilation and anti-static property of the mesh. Suitable for drying of pulp in paper-making, chemical fiber, continuous pre-press mesh belt and other anti-static industries.

Specifications

Material Composition

- Base Material: 100% polyester monofilament, ensuring both strength and flexibility.

- Anti-static Additive: The mesh incorporates carbon-loaded, metalized, or surface-treated fibers to achieve a surface resistivity in the range of 10^6 to 10^9 ohms/square (Ω/sq). This allows for effective static discharge while maintaining the mesh's integrity.

Mesh Size (Aperture)

- Range: Available from 10 mesh to 400 mesh.

- 10 mesh: Approximately 2.54 mm (0.10 inches) openings.

- 400 mesh: Approximately 0.038 mm (0.0015 inches) openings.

- Tolerance: Mesh count tolerance is ± 5%, providing consistent performance across various applications.

Hole Type (Weave Pattern)

- Standard Weave: Plain weave is the most common pattern.

- Optional Weaves: Available in twill weave, Dutch weave, or other specialized weaves upon request, depending on the specific application.

Wire Diameter (Yarn Diameter)

- Range: From 30 µm to 500 µm (0.0012 inches to 0.02 inches).

- Tolerance: ± 5 µm. The diameter varies with mesh count, with finer mesh requiring finer yarn for greater precision.

Fabric Thickness

- Range: Between 0.05 mm to 1.0 mm (0.002 inches to 0.04 inches).

- The thickness of the mesh varies depending on the mesh count and yarn diameter. Higher mesh counts usually result in thinner fabric.

Air Permeability

- Range: Variable, depending on mesh count and weave pattern.

- Measured in cubic feet per minute (CFM) or liters per square meter per second (L/m²/s).

- Higher mesh counts reduce air permeability due to smaller openings, while coarser meshes allow for greater airflow.

Tensile Strength

- Warp Direction: 50 N/cm to 500 N/cm.

- Weft Direction: 50 N/cm to 500 N/cm.

- Test Method: ASTM D5035 or equivalent, ensuring that the mesh holds up under operational pressures and stress.

- Color Options: Available in black, gray, or

white. Other colors are available upon request, subject to minimum order quantities. - Temperature Resistance: Withstands temperatures from -40°C to +150°C (-40°F to +302°F), making it suitable for a wide range of operating environments.

- Resistance: Excellent resistance to most common solvents, acids, and alkalis, ensuring durability in harsh industrial environments.

- Packaging: Supplied in rolls, wrapped in protective plastic film, and packaged in durable cardboard boxes to prevent damage during transit.

Advantages of Anti-Static Polyester Screen Mesh

- Durable Construction: Manufactured using imported German looms, ensuring tight and consistent weave with no deformation, offering long-lasting performance.

- Easy to Clean: The smooth surface, created by the tight warp and weft wires, prevents blockages and makes the mesh easy to clean, improving operational efficiency.

- Effective Static Control: The anti-static properties ensure that electrostatic charges are safely discharged, reducing the risk of static damage to sensitive equipment and preventing electrical hazards.

- Good Ventilation: Excellent air permeability due to the design of the mesh, which ensures optimal airflow in drying and filtration processes.

Applications

- Electronics Manufacturing: Used for screen printing in electronics production, where preventing electrostatic discharge is crucial to protect sensitive components.

- Filtration of Sensitive Components: Ideal for filtering delicate electronic components, as it helps reduce the risk of static buildup during handling or processing.

- Cleanroom Dust Control: Perfect for dust control in cleanroom environments, where the reduction of static charges is vital to maintain the cleanliness and safety of controlled areas.

- Conveyor Belts for Electronics Handling: Used in conveyor belts for handling electronic devices, where preventing static buildup ensures the integrity of the products.

Anti-Static Polyester Mesh for Filtration and Screening

Anti-Static Polyester Mesh Fabric

Woven Polyester Anti-Static Mesh Conveyor Belt

Technical Parameters:

| Filament Dia. (mm) | Density (root / cm) | Tensile strength (N / cm) | Weight Kg/m² | Thickness (mm) | Air permeability (m³ / m²h) | CFM 127/Pa | |||

| Warp | Weft | Warp | Weft | Surface | Joint | ||||

| 0.4 | 0.5 | 33 | 9 | 1600 | 900 | 0.80 | 1.3 | 2976 | 186 |

| 0.8 | 0.8 | 14.8 | 6.8 | 2000 | 900 | 2.2 | 2.2 | 4000 | 250 |

| 0.65 | 0.8 | 14.8 | 7.2 | 2000 | 1.6 | 1.95 | 6800 | 430 | |

Petter's Anti-Static Polyester Screen Mesh offers an effective solution for industries requiring static control, ventilation, and filtration. With customizable specifications, such as mesh size, wire diameter, and color, this mesh is adaptable for a range of applications, from electronics manufacturing to environmental protection. Its robust construction, combined with excellent static discharge properties and durability, makes it an ideal choice for industrial applications where precision, safety, and performance are paramount. Whether used for filtering sensitive components, dust control, or static-free material handling, this mesh provides a reliable and efficient solution.

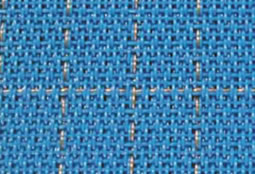

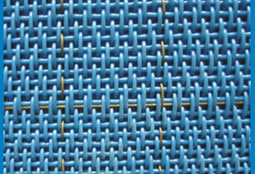

Synthetic & Bronze Wire Hybrid Mesh

Synthetic & Bronze Wire Hybrid Mesh is a high-performance material that combines the durability and flexibility of synthetic fibers with the strength and aesthetic appeal of bronze wire. This unique mesh offers the best qualities of both materials, resulting in a versatile product for a variety of applications, including architectural designs, filtration, and security. The combination of synthetic fibers (typically polyester or nylon) and bronze wire ensures excellent corrosion resistance and flexibility, making it ideal for applications that require both strength and visual appeal. The synthetic fibers provide durability, weather resistance, and low maintenance, while the bronze wire adds an elegant metallic finish that naturally ages over time.

Specifications

Material Composition:

- Synthetic Fibers: Polyester or nylon (flexible, UV-resistant, durable).

- Bronze Wire: Copper-tin alloy (corrosion-resistant, strong, develops patina).

Mesh Type:

- Woven: Synthetic fibers and bronze wire in plain, twill, or custom weaves.

Wire Diameter:

- Synthetic: 0.2 mm to 2 mm.

- Bronze: 0.5 mm to 5 mm.

Mesh Size (Aperture):

- Range: 1 mm to 10 mm.

- Tolerance: ± 5%.

Thickness:

- Fabric: 0.5 mm to 2.0 mm (varies with wire gauge and weave).

Color:

- Synthetic: Black, gray, or natural.

- Bronze: Natural (develops patina).

Temperature Resistance:

- Synthetic: -40°C to +150°C (-40°F to +302°F).

- Bronze: Up to 300°C (572°F).

Corrosion Resistance:

- Bronze: Excellent.

- Synthetic: Resistant to UV, weathering, chemicals.

Applications

Architectural:

- Wall Cladding: Decorative, durable, modern.

- Facades: Decorative elements, sunshades, safety barriers.

- Ceiling Panels: Visually appealing, strong, stylish.

Security:

- Security Fencing: High-security fences, gates, barriers.

- Protective Grills: Residential and commercial, balanced visibility and security.

Filtration:

- Industrial: Liquid, gas, and solid filtration.

- Water: Water treatment systems.

Interior Design:

- Room Dividers: Elegant partitioning, privacy, light filtration.

- Furniture Accents: Contemporary look, ventilation.

Automotive & Aerospace:

- Ventilation Systems: Air filtration, lightweight, durable.