Polyester Bolting Cloth Belt for Food Drying and Papermaking

Polyester bolting cloth is a high-performance industrial mesh fabric, primarily made from polyester monofilament woven through specialized techniques. It features high tensile strength, low elongation, chemical resistance, heat resistance, and good air permeability. This makes it a versatile solution for various applications across industries, including screening, filtering, and printing, often replacing traditional stainless steel wire cloth. Polyester bolting cloth is characterized by its precise weave, smooth surface, and exceptional dimensional stability. It excels in applications demanding accurate particle separation, durability, and resistance to chemicals and abrasion. Compared to stainless steel wire cloth, polyester bolting cloth is often lighter, more flexible, and less prone to blinding or clogging.

Petter supplies two types of bolting cloths: polyester bolting cloth and stainless steel woven wire bolting cloth. They are used for silk printing, fine grading in flour mills and shale shaker screening. Polyester material bolting cloth has several benefits compared with stainless steel (mainly SUS316 ) bolting cloth, for example: high tension, less weight and less cost, etc. In this page, we mainly introduce polyester bolting cloth, the weaving machine, its uses, benefits and sizes.

Powders and granular materials are sometimes described as having a certain mesh size. Polyester wire bolting cloth can be supplied with micron mesh sizes and thin fabrics, suitable for Textile Printing, Ceramic Printing, Glass Printing, Graphics Printing, Electronic Printing, CD/DVD Printing. With such applications, the polyester bolting cloth is also called printing screen. It is also known as filter cloth or filter screen when it is used in industrial filtration.

Specifications

- Material: 100% Polyester Monofilament Yarn

- Weaving Pattern: Plain weave, twill weave, double thread weave, semi-interlock weave.

- Mesh Count: 6 mesh (15 threads per inch) to 400 mesh (160 threads per inch)

- Thread Diameter: 0.03 mm to 0.60 mm

- Aperture Size: Ranges from 20 µm to 1000 µm (and larger), e.g., 60 mesh with an opening of about 0.25mm to 400 mesh with an opening of about 0.038mm

- Open Area: 20% to 70% (varies with mesh count and thread diameter)

- Roll Width: Typically 100 cm to 365 cm (custom widths available)

- Roll Length: Typically 30 m, 50 m, 100 m (custom lengths available)

- Thickness: 0.1 mm to 2.5 mm (depending on mesh count and monofilament diameter)

- Color: White (standard), yellow, other colors (on request)

Classification

By Weaving Pattern:

- Plain weave: Most common, offering good stability and flow.

- Twill weave: Enhanced flexibility for curved surfaces or dynamic applications.

- Dutch weave: Provides finer filtration and increased strength.

By Application:

- Printing Mesh: Screen printing on textiles, ceramics, glass, electronics, CDs/DVDs, etc.

- Filtering Mesh: Fine powder and granular material screening and filtering.

- Food Processing Mesh: Flour sieving, grain processing, etc.

- Papermaking Mesh: Paper formation, drying, and pressing.

- Industrial Conveyor Mesh: Conveying various materials.

By Material Shape:

- Round Monofilament Mesh: Higher strength and wear resistance.

- Flat Monofilament Mesh: Better flexibility and air permeability.

Packaging

- Polyester bolting cloth is typically packaged in protective plastic film-wrapped rolls.

- Rolls are usually shipped in sturdy cardboard tubes or boxes to prevent damage during transport.

- Custom packaging options are available for specific requirements

Key Advantages of Polyester Bolting Cloth:

- High precision and accuracy in filtration and separation.

- Excellent durability and resistance to wear.

- Good chemical compatibility with a wide range of substances.

- Easy to clean and maintain.

- Cost-effective compared to stainless steel wire cloth.

- Lightweight and flexible for easier handling and installation.

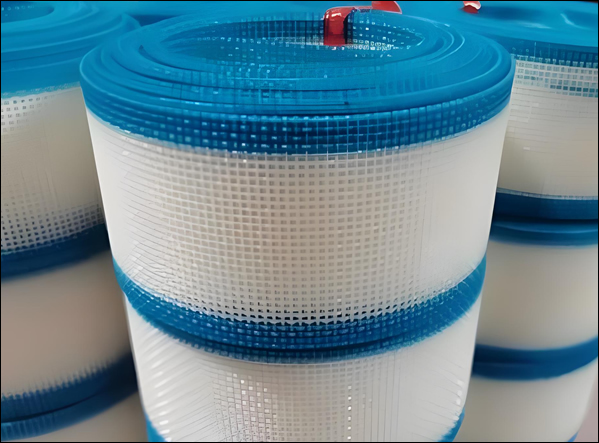

Polyester Bolting Cloth for Wastewater Treatment

Polyester Bolting Cloth

- Weaving Series: Three-Layer Weave, 24 Shed

- Application: Wastewater Treatment

- Color: Blue

- Application: Non-woven Fabric Manufacturing

- Structure: Single-Layer Weave, 5 Shed

- Mesh Count: 120 Mesh

- Thickness: 0.81 mm

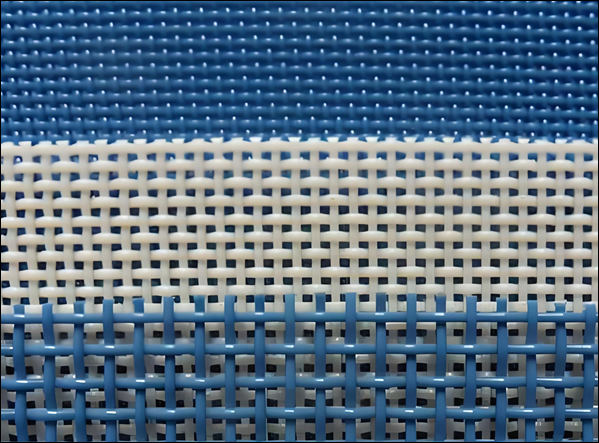

Plain Weave (1-over-1) in Woven Polyester Bolting Cloth

Weaving Structure

- 1-over-1 structure: Each weft thread passes alternately over and under each warp thread.

- Forms a tight and consistent mesh pattern with precise apertures.

- Ensures uniform tension across the fabric.

Polyester Bolting Cloth Conveyor Belt for Food Drying

Specification Comparison

| Property | Polyester Bolting Cloth | Stainless Steel Wire Cloth |

|---|---|---|

| Material | Synthetic Polyester fibers | Stainless Steel (304, 316, 316L) |

| Mesh Count | 6–400 mesh/inch | 2–635 mesh/inch |

| Wire/Thread Diameter | 0.031–0.60mm | 15–500 micron |

| Mesh Size | 0.038mm–0.25mm opening | 15–500 micron opening |

| Width | 100cm–365cm | 1000mm–2000mm |

| Thickness | 0.1mm–2.5mm | 40–800 micron |

| Temperature Resistance | Up to 150°C | Up to 800°C |

| Chemical Resistance | High resistance to acids and alkalis | Superior resistance, including harsh acids |

| Corrosion Resistance | High | Excellent |

| Tensile Strength | High | Very high |

| Flexibility | Excellent | Moderate |

| Air Permeability | Good | Moderate |