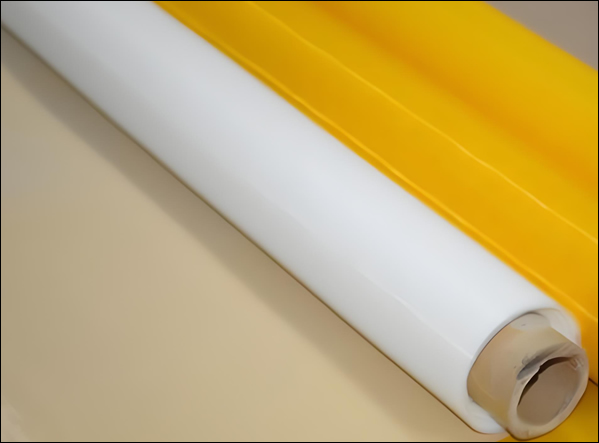

Polyester Screen Printing Mesh Specifications: (30-355 Mesh, 0.05-0.18mm)

Polyester Screen Printing Mesh is a high-quality, durable material designed for precision printing applications. Made from 100% polyester monofilament, it offers excellent tensile strength, stability, and ink permeability, ensuring sharp and accurate prints. Available in a wide range of mesh counts (30-355 mesh) and wire diameters (0.05mm-0.18mm), it is suitable for fine-detail graphics, textiles, electronics, and industrial printing. The mesh is resistant to chemicals, heat (-40°C to +150°C), and stretching, making it a reliable choice for consistent printing performance. Available in white, yellow, and black, it can be customized in various widths and roll lengths to meet specific printing needs.

Monofilament Polyester Mesh for Screen Printing

13-600 Mesh PET Polyester Screen Printing Mesh

Monofilament Polyester Mesh Screen for Printing

Polyester Screen Printing Mesh Specifications

- Material: 100% polyester monofilament (durable, flexible, chemical/heat resistant).

- Weave: Plain (standard, uniform ink flow), Twill (durable, higher tension),Dutch (fine detail, ink control)

- Thread Diameter: 27 - 200 µm (0.0011 - 0.0079 inches) , 27, 55, 80, 120, 200 µm

- Aperture: 20 - 600 µm (0.0008 - 0.0236 inches), 20, 40, 80, 200, 600 µm

- Open Area: 15% - 50% (higher = more ink flow, lower = finer detail)

- Roll Length: 30, 50, 100 meters (98.4, 164, 328 feet)

- Roll Width: 1000 - 3500 mm (39.4 - 137.8 inches), 1270, 1650, 2500 mm (50, 65, 98.4 inches)

- Color: White, Yellow,Black

- Packaging: Plastic film, cardboard box/crate

- Tensile Strength: Warp/Weft: 35 - 900 N/cm

- Fabric Weight: 40 - 280 g/m², 40 (lightweight), 120 (medium), 280 (heavy-duty)

- Elongation: 5% - 25% (lower = more stable)

- Dimensional Stability: Excellent (maintains size/shape under tension)

- Mesh Count: 30 - 420 mesh (1.18 - 16.5 threads/mm), 43 mesh (1.7/mm, 1.2/inch), 77 mesh (3.0/mm, 2.0/inch),120 mesh (4.7/mm, 3.1/inch),180 mesh (7.1/mm, 4.6/inch),305 mesh (12.0/mm, 7.7/inch),355 mesh (14.0/mm, 9.0/inch) .

High-Quality 100% Polyester Monofilament Screen Printing Mesh

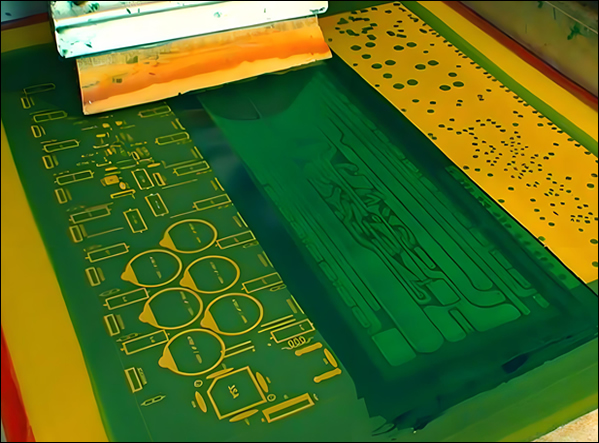

Industrial Screen Printing Machine for Polyester Mesh Fabrics

Size details of polyester printing mesh:

| Mesh count dia. (mesh / cm μm) | Mesh count (mesh/ inch) | aperture (μm) | Thread dia.(μm) | opening (%) |

thickness (μm) |

Thickness tolerance (+/-μm) |

theoretical link (cm3/m2) |

weight (g/m2) |

| 13 - 150 PW (SL) | 33 | 619 | 150 | 64 | 300 | 14 | 128 | 60 |

| 20 - 180 PW (S) | 55 | 296 | 180 | 69 | 120 | 9 | 79 | 35 |

| 21 - 150 PW (SL) | 55 | 326 | 150 | 46 | 260 | 14 | 118 | 121 |

| 24 - 100 PW (T) | 60 | 316 | 100 | 57 | 136 | 11 | 65 | 81 |

| 28 - 140 PW (SL) | 70 | 217 | 140 | 40 | 195 | 13 | 76 | 125 |

| 32 - 55 PW (S) | 81 | 257 | 55 | 67 | 103 | 6 | 67 | 28 |

| 32 - 64 PW (S) | 81 | 248 | 64 | 63 | 95 | 6 | 56 | 32 |

| 32 - 100 PW (T) | 81 | 212 | 100 | 45 | 165 | 8 | 73 | 75 |

| 36 - 90 PW (T) | 92 | 183 | 90 | 44 | 150 | 8 | 65 | 68 |

| 39 - 55 PW (S) | 100 | 177 | 55 | 56 | 88 | 6 | 55 | 30 |

| 40 - 80 PW (T) | 103 | 166 | 80 | 44 | 133 | 7 | 59 | 60 |

| 43 - 80 PW (T) | 110 | 149 | 80 | 41 | 130 | 7 | 53 | 64 |

| 47 - 45 PW (S) | 120 | 166 | 45.2 | 61 | 80 | 6 | 42 | 40 |

| 47 - 55 PW (S) | 120 | 152 | 55 | 51 | 88 | 6 | 48 | 34 |

| 48 - 70 PW (T) | 122 | 133 | 70 | 41 | 115 | 6 | 47 | 55 |

| 53 - 45 PW (S) | 135 | 143 | 45.2 | 57 | 79 | 7 | 41 | 46 |

| 53 - 55 PW (S) | 135 | 133 | 55 | 50 | 86 | 6 | 42 | 40 |

| 54 - 64 PW (T) | 137 | 115 | 64 | 39 | 100 | 5 | 39 | 51 |

| 54 - 70 PW (HD) | 137 | 109 | 70 | 35 | 116 | 6 | 40 | 62 |

| 61 - 64 PW (T) | 155 | 90 | 64 | 31 | 101 | 5 | 30 | 58 |

| 64 - 55 PW (S) | 160 | 98 | 55 | 38 | 98 | 5 | 36 | 48 |

| 64 - 64 PW (T) | 160 | 85 | 64 | 30 | 115 | 6 | 34 | 61 |

| 68 - 55 W (S) | 175 | 85 | 55 | 34 | 85 | 4 | 28 | 48 |

| 68 - 64 PW (T) | 175 | 78 | 64 | 28 | 105 | 5 | 30 | 65 |

| 72 - 48 PW (S) | 182 | 90 | 48 | 36 | 78 | 5 | 33 | 39 |

| 72 - 55 PW (T) | 182 | 85 | 55 | 30 | 90 | 5 | 27 | 51 |

| 77 - 48 PW (S) | 195 | 77 | 48 | 35 | 80 | 4 | 28 | 42 |

| 77 - 55 PW (T) | 195 | 67 | 55 | 27 | 88 | 4 | 24 | 55 |

| 80 - 48 PW (T) | 200 | 72 | 48 | 33 | 74 | 4 | 25 | 56 |

| 90 - 48 PW (T) | 230 | 56 | 48 | 25 | 78 | 4 | 19 | 50 |

| 100 - 40 PW (T) | 255 | 58 | 40 | 33 | 63 | 3 | 21 | 34 |

| 110 - 40 PW (HD) | 280 | 48 | 40 | 27 | 64 | 3 | 17 | 40 |

| 120 - 31 PW (S) | 305 | 49 | 31 | 35 | 49 | 3 | 17 | 26 |

| 120 - 34 PW (T) | 305 | 45 | 34 | 30 | 55 | 3 | 16 | 35 |

| 120 - 40 PW (HD) | 305 | 37 | 40 | 20 | 63 | 3 | 13 | 44 |

| 130 - 34 PW (T) | 330 | 40 | 34 | 27 | 55 | 3 | 15 | 37 |

| 140 - 31 PW (S) | 355 | 36 | 31 | 26 | 48 | 2 | 12 | 30 |

| 140 - 34 PW (T) | 355 | 31 | 34 | 20 | 53 | 3 | 10 | 39 |

| 140 - 34 TW (T) | 355 | 33 | 34 | 21 | 56 | 3 | 12 | 41 |

| 150 - 31 PW (S) | 380 | 32 | 31 | 23 | 49 | 3 | 11 | 32 |

| 150 - 34 PW (T) | 380 | 23 | 34 | 13 | 55 | 3 | 6.5 | 42 |

| 165 - 31 PW (S) | 420 | 23 | 31 | 15 | 48 | 2 | 7 | 36 |

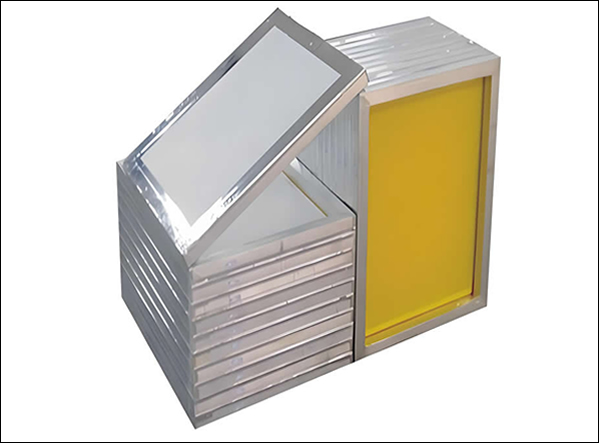

Manufacturing steps for Polyester Mesh Fabrics

Our Polyester Mesh Manufacturing Process

- Interested in learning how our high-quality polyester mesh fabrics are made? We invite you to delve into our manufacturing process, where precision and quality control are paramount at every stage. From the careful selection of raw materials to the meticulous weaving and finishing processes, we ensure that our polyester mesh meets the highest standards of durability, consistency, and performance.

Versatility of Polyester Screen Printing Mesh

- Petter polyester screen printing mesh is a versatile solution for various industrial printing applications. Compatible with a wide range of screen printing machines, our mesh is engineered to deliver exceptional results across diverse sectors.

Applications

- Graphics:

- Glass containers

- Labels

- Large format UV graphics

- Small format UV graphics

- Solvent graphics

- Tubes and cartridges

- Electronics:

- CDs/DVDs

- Printed electronics

- Solar cells

- Other:

- Ceramics decorating

- Package printing

- Printing on glass

- Textile printing

- Tableware

Other Petter Polyester Mesh Products:

Petter monofilament polyester mesh fabrics are widely used for beneficiation, flour sifting and grading, wastewater treatment, sugar refining, pharmaceuticals, ceramics, food( fruit and vegetable juice pressing), paper-making drying, printing and coal washing industry.

Applications:

- Industrial:

- Beneficiation

- Wastewater treatment

- Coal washing

- Food & Beverage:

- Flour sifting and grading

- Sugar refining

- Fruit and vegetable juice pressing

- Other:

- Pharmaceuticals

- Ceramics

- Paper-making drying

Connect with Us

We welcome you to contact us for more information about our polyester mesh products and manufacturing capabilities. Our team is ready to assist you in finding the perfect mesh solution for your specific needs.