Polyester Plain Weave Mesh Screen: Size and Weave Type Options

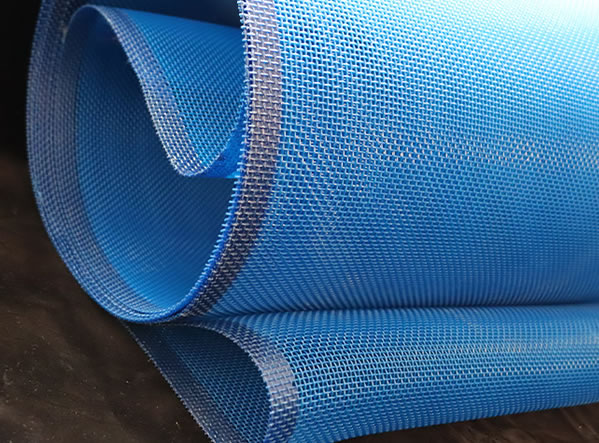

Pertter Polyester Mesh Fabric Co., a manufacturer and exporter of polyester mesh products, offers a comprehensive selection of polyester plain weave mesh screens. We provide a variety of types and specifications to meet diverse industrial needs. Designed for optimal performance in filtering, sieving, and separation processes, these mesh screens are primarily made from high-quality polyester fibers. Their unique weaving pattern ensures reliable durability and functionality in demanding environments. Polyester Plain Weave Mesh is widely used across industries such as papermaking, packaging, fiber processing, and other specialized filtering tasks.

Types of Polyester Plain Weave Mesh Screens

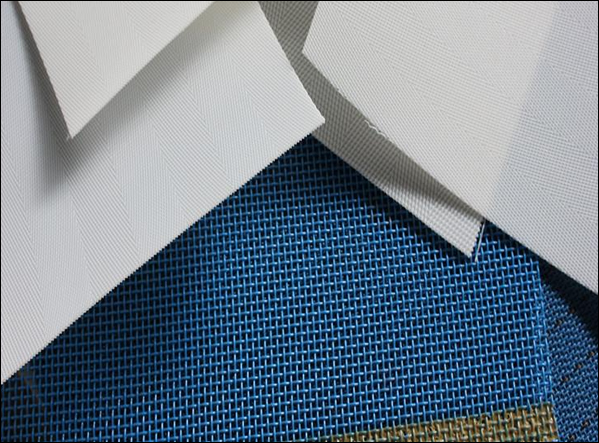

Polyester Plain Weave Mesh Screens are available in two primary weave constructions: Two-Shed and Three-Shed.

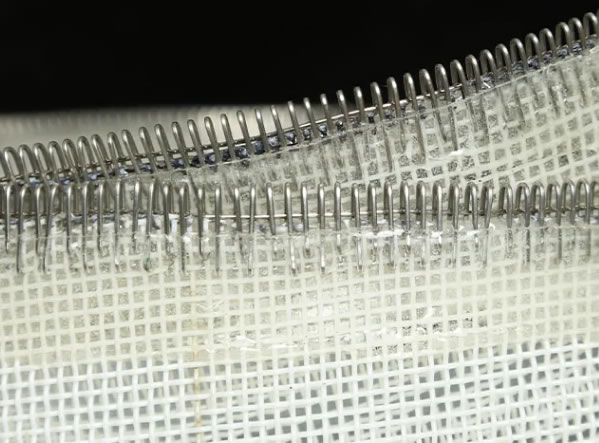

- Two-Shed Plain Woven Mesh: The two-shed weave features two sets of warp threads that pass alternately through the weft threads. This structure results in a mesh that allows for larger particle sizes to pass through while maintaining good flow rates. Common applications include paper pulp processing, fiber paper production, and packing paper manufacturing.

- Three-Shed Plain Woven Mesh: The three-shed weave involves a more complex interlacing of warp and weft threads, creating a denser mesh that offers finer filtration. It is ideal for applications requiring high precision filtration, such as in the production of special wire mesh products for various industrial processes.

Comparison of Two-Shed and Three-Shed Weaves

| Feature | Two-Shed Weave | Three-Shed Weave |

|---|---|---|

| Flow Rate | Higher | Lower |

| Filtration Efficiency | Moderate | Higher |

| Particle Size Retention | Larger | Smaller |

| Mesh Openness | More Open | Denser |

| Applications | Coarse filtration, high flow applications | Fine filtration, high precision applications |

Common Specifications and Sizes

Mesh Count: The number of openings per inch is one of the primary indicators of the mesh's filtration capacity. Common mesh counts range from 30 mesh (for coarser applications) to 500 mesh (for fine filtration).

- 30 Mesh: Suitable for applications with larger particle sizes such as pulp and aggregate separation.

- 60 Mesh: Often used for general sieving and filtering in paper production processes.

- 100 Mesh: Ideal for fine particle separation in both liquid and solid filtering processes.

- 200 Mesh: Commonly used in specialized applications requiring precise filtration.

- 500 Mesh: Typically used for high-precision separation, such as in pharmaceuticals and fine chemical processing.

Wire Diameter: Polyester mesh screens come in varying wire diameters, which affect the mesh's strength and pore size. Common wire diameters include:

- 0.10mm – 0.20mm: For applications requiring medium-strength filtering.

- 0.30mm – 0.40mm: Ideal for heavy-duty filtering, especially in industrial and pulp production processes.

Roll Width and Length:

- Standard Width: Polyester plain weave mesh is typically available in 1 meter, 1.2 meters, and 2 meters widths. However, custom widths can also be manufactured to suit specific applications.

- Standard Length: Roll lengths usually range from 10 meters to 100 meters, depending on customer requirements.

Material and Weave Structure:

- Our polyester plain weave mesh screens are constructed from high-tenacity polyester yarns. These yarns possess excellent chemical resistance to acids, alkalis, and common solvents, as well as good abrasion resistance.

- The plain weave structure provides a stable and uniform mesh opening, ensuring consistent performance in filtration and separation processes. The specific yarn diameter and mesh count are carefully selected to achieve the desired filtration efficiency and flow rate for each application.

Applications of Polyester Mesh Screens

- Pulp Processing & Packing Paper: Ensures consistent material flow and efficient dewatering.

- Specialty Fiber Papers: Provides crucial fine filtration.

- Ingredient Separation & Sifting: Offers a reliable and hygienic solution.

- Fine Chemical Filtration & Separation: Ensures high-quality output and efficiency.

- Water Treatment Fine Filtration: Removes impurities and particulates.

| Weaving Series and Types | Thread Diameter mm | Density (pieces / cm) | Strength (N/cm) | Weight kg/m2 | Thick- ness mm |

Air Perme- ation m3 / m2h |

||||

| Warp | Weft | Warp | Weft | Mesh Surface | Inserting Place | Spiral Conne -cting Ring |

||||

| Two-Shed Plain Woven Mesh | 0.70 | 0.70 | 8 | 7 | 1600 | 900 | 600 | 0.77 | 1.3 | 11000 |

| 0.45 | 0.45 | 10 | 8.6 | 1600 | 850 | 600 | 0.45 | 0.88 | 16000 | |

| 0.50 | 0.50 | 13.5 | 8.5 | 1800 | 900 | 600 | 0.63 | 0.95 | 6500 | |

| Three-Shed Plain Woven Mesh | 0.50 | 0.60 | 10 | 9 | 1600 | 900 | 650 | 0.59 | 1.15 | 14000 |

| 0.70 | 0.80 | 8 | 8 | 1600 | 900 | 650 | 0.80 | 1.35 | 10000 | |

| 0.30 | 0.35 | 22 | 14.5 | 1200 | 750 | 600 | 0.31 | 0.60 | 13000 | |

| 0.30 | 0.40 | 22 | 14 | 1200 | 750 | 600 | 0.35 | 0.70 | 13500 | |